| Availability: | |

|---|---|

| Quantity: | |

Waukesha VGF F24SE Gas Engine

Breaking through traditional single-phase heat exchange limitations, we achieve efficient gas-liquid dual-phase heat transfer in the VGF F24SE cooling system. Coolant undergoes controlled boiling in specially designed microchannels, absorbing massive heat through latent heat of vaporization. The air side utilizes turbulator-enhanced fins to disrupt boundary layers, increasing heat transfer coefficient by 2.3 times. This technology increases heat exchange capacity by 65% within the same volume, perfectly handling engine transient load variations.

Features

Key components such as fins and fans are manufactured with high-quality anti-corrosion materials and processes, offering excellent durability and a long service life.

Dry Cooler List

Jenbacher | J208,J312,J316,J320,J412,J416,J420,J612,J616,J620,J624,J920 |

MAN | 51/60G,35/44G |

MTU | 8V4000,12V4000,16V4000,20V4000 |

| MWM | TCG 2032,TCG 3020,TCG 2020, TCG 3016 |

Waukesha | 16V 275GL,12V 275GL,F18SE,F24SE,L36GSI,P48GSI,P9394GSI ,L7044GSI,L7042GSI |

Maintance and Service

Predictive Maintenance Support – Leverage remote monitoring and data analysis services to identify potential issues before they cause downtime.

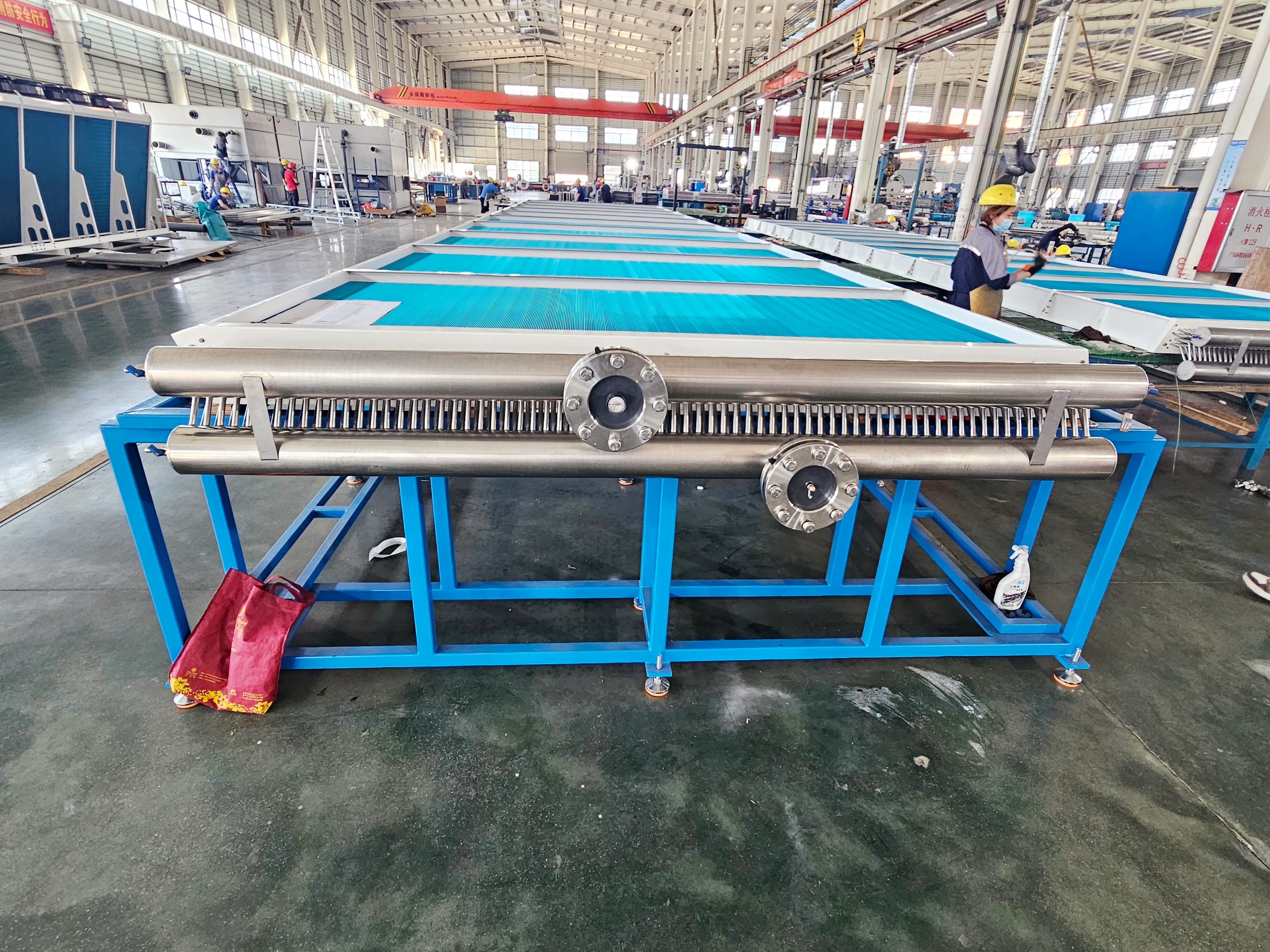

How We Produce

Behind our quality excellence is a deeply ingrained culture of continuous improvement. We systematically collect and analyze production and market data, treating customer feedback as invaluable input for optimizing product design and processes. We proactively engage in technical dialogues with our clients to collaboratively develop solutions for application-specific challenges, ensuring we deliver not just a standard product, but a verified value enhancement.

Pictures of Sinrui's production workshop