| Availability: | |

|---|---|

| Quantity: | |

MWM TCG 2020 Engine

We developed a carbon footprint optimization system for the MWM TCG 2020 engine. By recovering engine waste heat for adsorption refrigeration, the comprehensive energy efficiency of the cooling system is improved by 25%. Eco-friendly coating materials fully comply with RoHS standards, with overall recyclability reaching 92%. Third-party verification confirms this design helps reduce carbon emissions by approximately 18 tons annually.

Features

With a simple system design and fewer core components, it ensures low failure rates and high reliability. Routine maintenance only requires basic cleaning and inspection, minimizing upkeep costs.

Dry Cooler List

Jenbacher | J208,J312,J316,J320,J412,J416,J420,J612,J616,J620,J624,J920 |

MAN | 51/60G,35/44G |

MTU | 8V4000,12V4000,16V4000,20V4000 |

| MWM | TCG 2032,TCG 3020,TCG 2020, TCG 3016 |

Waukesha | 16V 275GL,12V 275GL,F18SE,F24SE,L36GSI,P48GSI,P9394GSI ,L7044GSI,L7042GSI |

Maintance and Service

Custom Cooling Solutions – We design radiators tailored to your specific engine needs and environmental conditions.

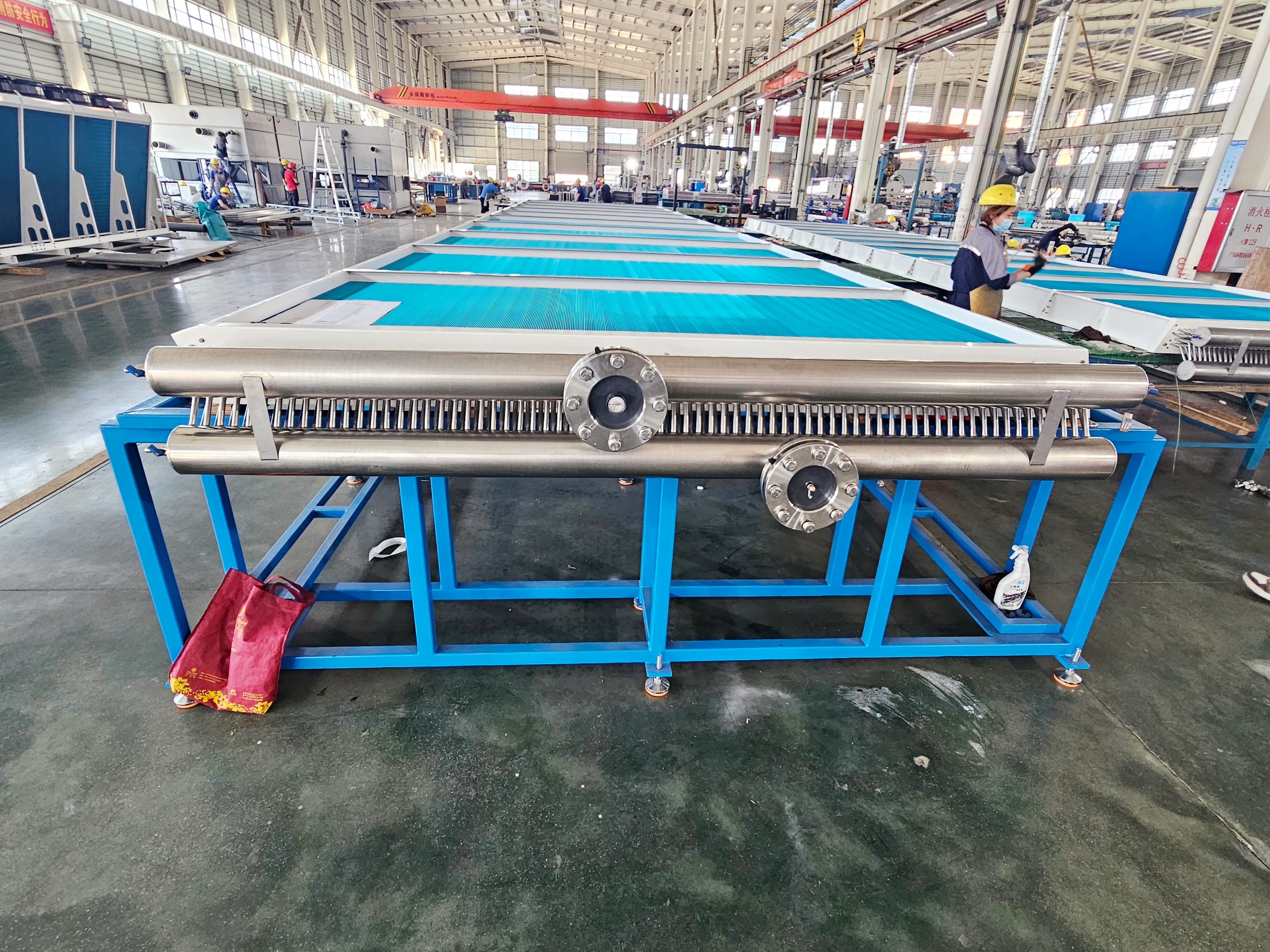

How We Produce

We have invested in a CNAS-accredited laboratory, ensuring all performance and durability test data carry authority and international credibility. Every test, from spectroscopic material analysis to full-unit vibration fatigue testing, is conducted within this controlled lab environment. This means every test report you receive is a reliable testament to the product's superior performance, giving you full confidence in your project design and procurement decisions.

Pictures of Sinrui's production workshop