| Availability: | |

|---|---|

| Quantity: | |

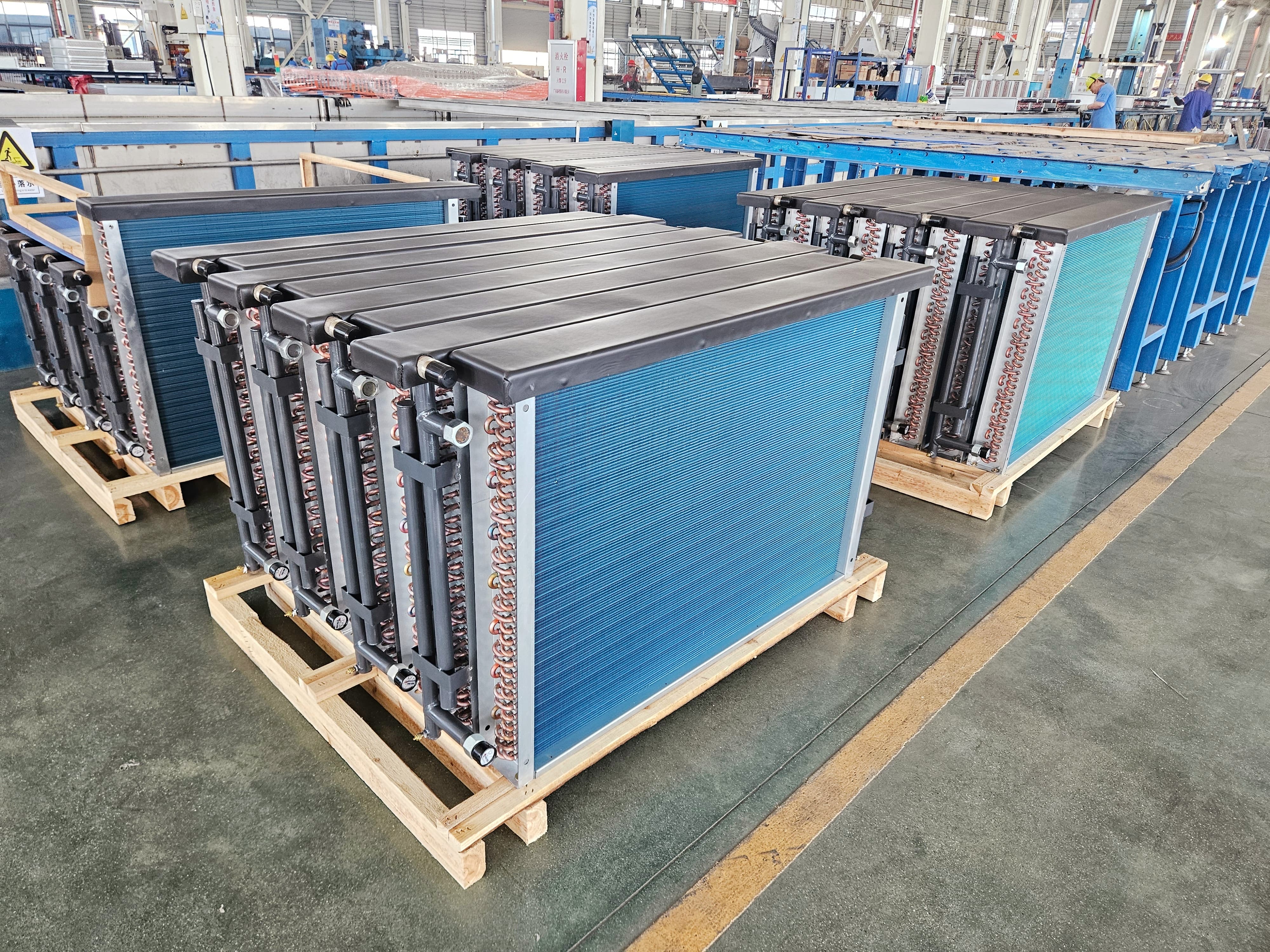

The Waukesha 16V 275GL Dry Cooler is engineered for large gas generator sets, using a copper tube and aluminum fin core for high-efficiency heat rejection.

Rapid Cooling – Copper-aluminum structure maximizes heat transfer.

Durable Core – Designed for continuous-duty generator applications.

Stable Engine Performance – Maintains consistent coolant temperature.

Dry Cooler List

| MWM | MWM TCG 2032, MWM TCG 3020, MWM TCG 2020, MWM TCG 3016 | |||

| Cummins | Cummins HSK 78G, Cummins GTA 50E, Cummins QSK 60G | |||

| MTU | MTU 8V4000, MTU 12V4000, MTU 16V4000, MTU 20V4000 | |||

| Jenbacher | Jenbacher J208, Jenbacher J312, Jenbacher J316, Jenbacher J320, Jenbacher J412, Jenbacher J416, Jenbacher J420, Jenbacher J612, Jenbacher J620 | |||

| MAN | MAN 51/60G, MAN 35/44G | |||

| Waukesha | Waukesha 16V 275GL, Waukesha12V 275GL, Waukesha VGF F18SE, Waukesha VGF F24SE, Waukesha VGF L36GSI, Waukesha VGF P48GSI, Waukesha VHP P9394GSI S5, Waukesha VHP L7044GSI S5 | |||

We use industrial-grade copper tubes and aluminum fins, assembled with controlled brazing techniques to guarantee leak-free and durable construction. The design process incorporates CFD airflow simulation and thermal analysis to optimize heat dissipation. All dry coolers undergo hydrostatic pressure testing, vibration testing, and performance verification, ensuring reliable cooling performance for high-capacity gas engines. Each unit is carefully packaged to protect the core during transport.

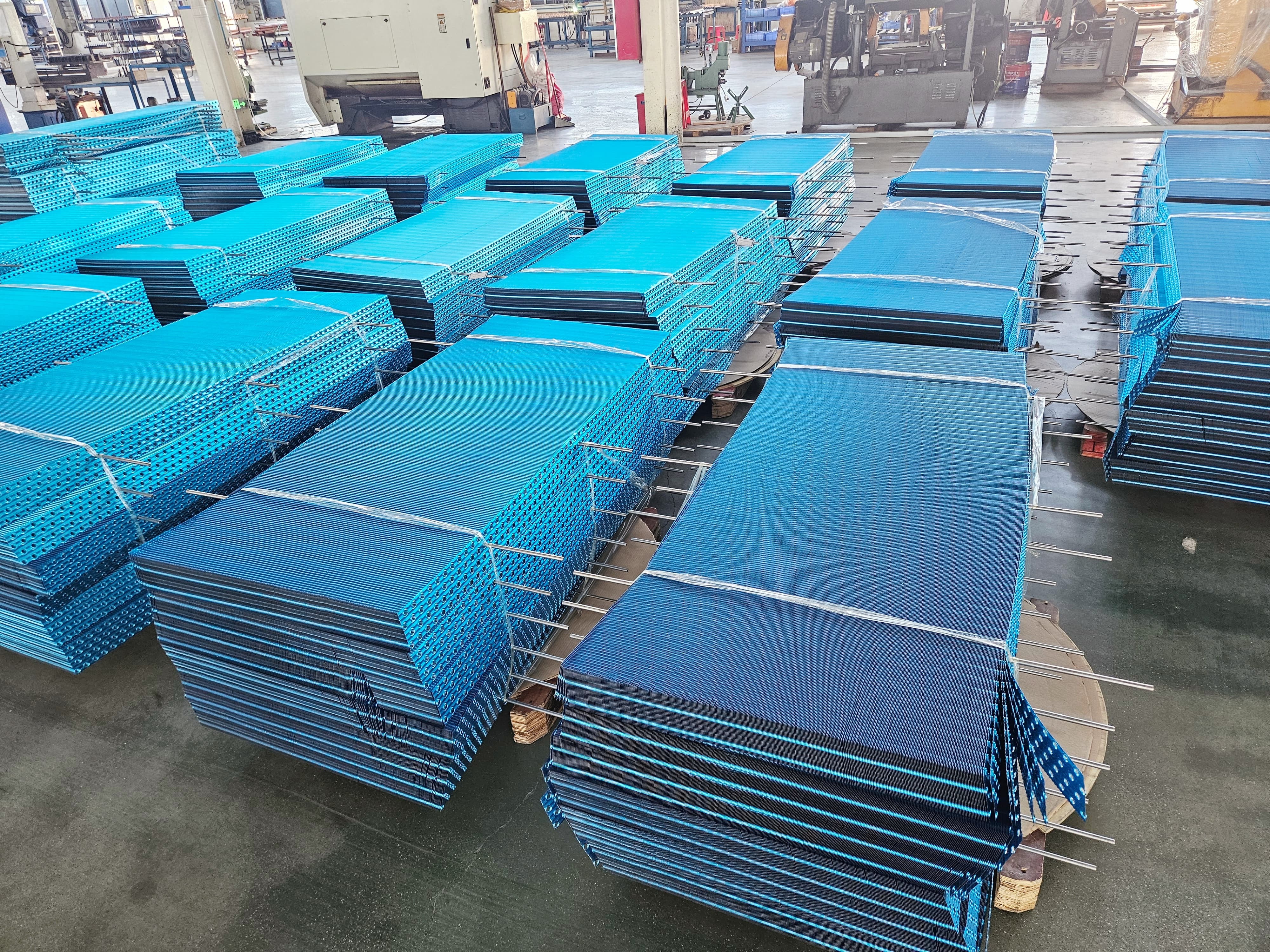

Pictures of Sinrui's production workshop

Radiator product packaging and delivery