| Availability: | |

|---|---|

| Quantity: | |

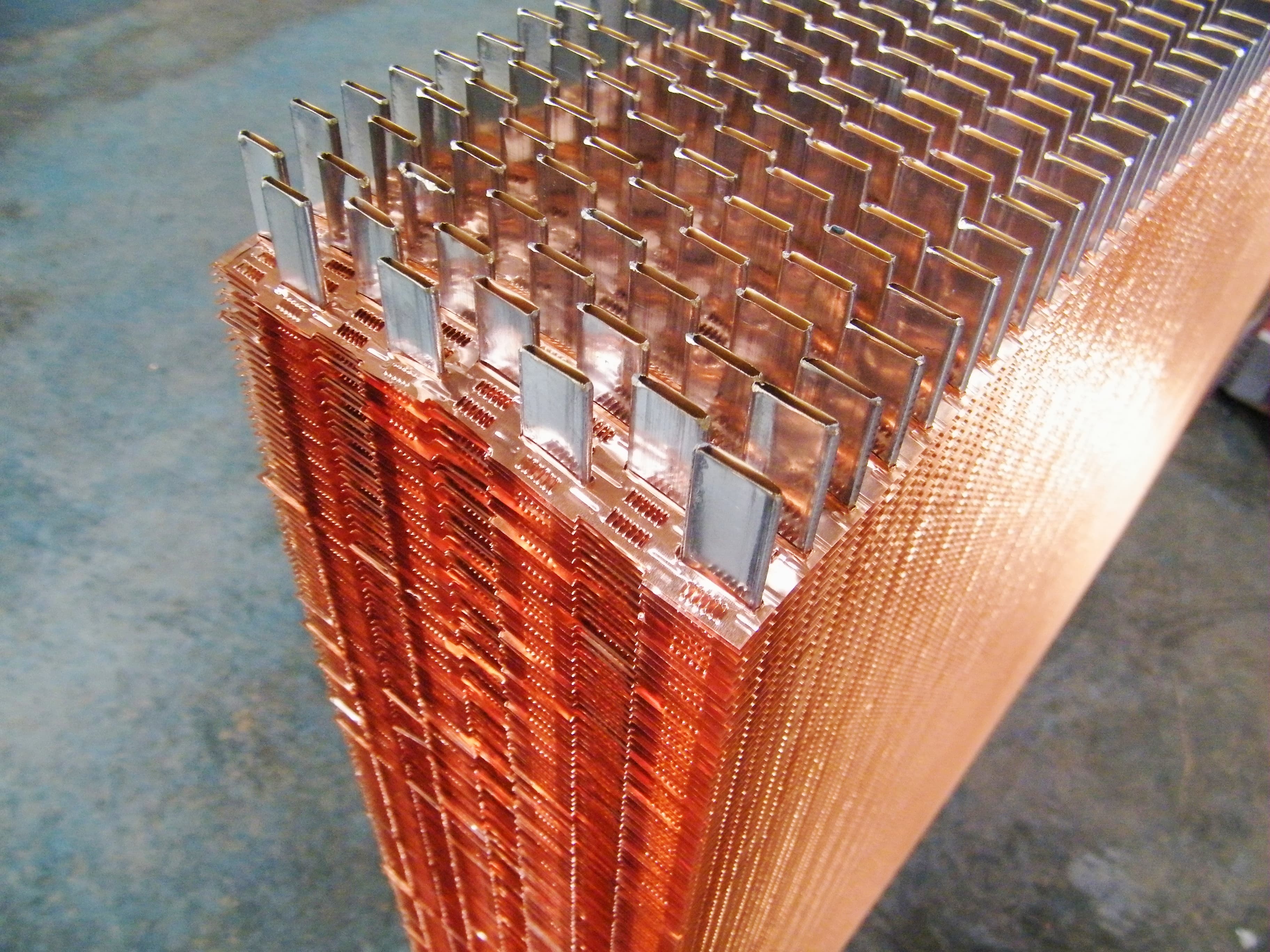

The Mitsubishi S12H-PTA Generator Radiator is a high-efficiency copper-core cooling assembly designed for Mitsubishi S12H-PTA diesel generator sets. Engineered for continuous and heavy-duty power generation, it provides excellent thermal stability and consistent cooling performance, ensuring the generator runs safely and efficiently in all conditions. The design meets OEM specifications, offering a precise fit and reliable performance for both new units and replacements.

Copper Core Design – Provides outstanding heat transfer capacity for stable temperature regulation during long operation cycles.

Coastal Application Ready – Optional anti-corrosion protective coating helps resist damage from salt-laden air and humidity.

Genertor Radiator List

| Cummins | 4BT3.9 G2, 6BT 5.9, 6BTA, 6 C8, 6CTA, LTA 10, NT855 G6, NTA 855, KTA19, KTA38, KTA38 G1, KTA38 G2A, KTA38 G3, KTA38 G5, KTA50 G1, KTA50 G3, KTA50 G8, QSB6.7, QSK23 G3, QSK23 G7, QSK45 G4, QSK45 G6, QSK50 G4, QSK50 G7, QSK60 G3, QSK60 G6, QSK78, QSK78 G12, QSK78 G9, QSK78 G6, QSK90, VTA28, VTA28 G5, VTA28 G7 | |||

| MTU | 12V2000 G25, 16V2000 G25, 16V2000 G45, 16V2000 G60, 16V2000 G63, 18V2000 G65, 18V2000 G85, 12V4000 G21, 12V4000 G23, 12V4000 G43, 12V4000 G63, 16V4000 G21, 16V4000 G23, 16V4000 G43, 16V4000 G61, 16V4000 G63, 16V4000 G81, 16V4000 G83, 20V4000 G23, 20V4000 G63, 20V4000 G83 | |||

| Mitsubishi | S6R PTA, S6R2 PTA, S12R PTA, S12R PTA2, S12A2 PTA, S12R PTAA2, S16R PTA, S16R PTA2, S16R PTAA2, S16R2 PTAW, S16R2 PTA, S6R MPTA, S6R MPTAW, S6R MPTK, S12R MPTA, S12A2 MPTAW, S12R Z3 PMTAW | |||

| Perkins | 4006, 4006 23TAG3A, 4006 TAG, 4006 TAG 2, 4008 TAG 2A, 4012 46TAG 3A, 4012 46TWG 2A, 4012 46TWG 4A, 4016 61TRG1, 4016 61TRG2, 4016 61TRG3 | |||

| CAT | 3508B, 3512, 3512B, 3512B TA60, 3516TA, C15, C175 16, G3520 C | |||

Each radiator is constructed using premium copper tubes and precision-formed fins, joined by brazing and soldering for excellent strength and leak resistance. Our production incorporates thermal flow simulation and structural testing to ensure maximum performance and durability. For customers in coastal or high-humidity areas, we offer an optional anti-corrosion surface coating to enhance longevity. Every unit is pressure-tested, vibration-tested, and thermally verified before export, ensuring consistent reliability in demanding generator applications.

Pictures of Sinrui's production workshop

Radiator product packaging and delivery