| Availability: | |

|---|---|

| Quantity: | |

The 393-5050 built with a high-strength all-aluminum plate-fin structure, it is engineered to handle extreme thermal loads, high pressure, and continuous operation. This radiator core is a direct OEM-spec replacement, ensuring perfect fit and long service life in demanding mining and construction environments.

Features

Heavy-Duty Durability – Epoxy-free construction with reinforced joints to withstand vibration, dust, and extreme temperatures.

Corrosion & Pressure Resistance – Premium aluminum alloy resists oxidation, coolant erosion, and high operating pressures.

Proven Reliability – Each unit tested for leakage, performance, and endurance to meet international quality standards.

Aluminum Radiator List-

| CAT | 213-8188, 185-7980, 243-5063, 320-0214, 186-0117, 230-5006, 236-8741, 245-4622, 250-4453, 3N-4363, 3N-4364, 230-2966, 186-9526, 272-5592, 2W0181 |

| Komatsu | 56E-07-21133, 561-03-81280, 561-03-81632, 561-03-81652, 561-03-81642, 21N-03-37412, 21N-03-41110, 21N-03-43510, 21T-03-31160, 21T-03-31711 |

| Liebherr | 10000392, 5617986, 5617987, 11823532, 11821219, 11821218, 5611936, 5611937, 10333648, 10333649, |

| Hitachi | 1386-621-100, 1381-639-801, 1381-639-8020, 1381-639-8030, 4682425, 4682426, 4444691, 4658096, 4427925, 4729782, 4421620, 335611, 4439687, YA00008446 |

How We Produce

Only certified high-conductivity aluminum alloy is selected to ensure lightweight strength and high thermal performance. Advanced brazing process guarantees leak-tight joints, structural stability, and extended product lifespan. CNC machining ensures exact OEM dimensions for fittings, flanges, and mounting points. Anti-corrosion coating and cleaning processes protect against oxidation and extend service life.

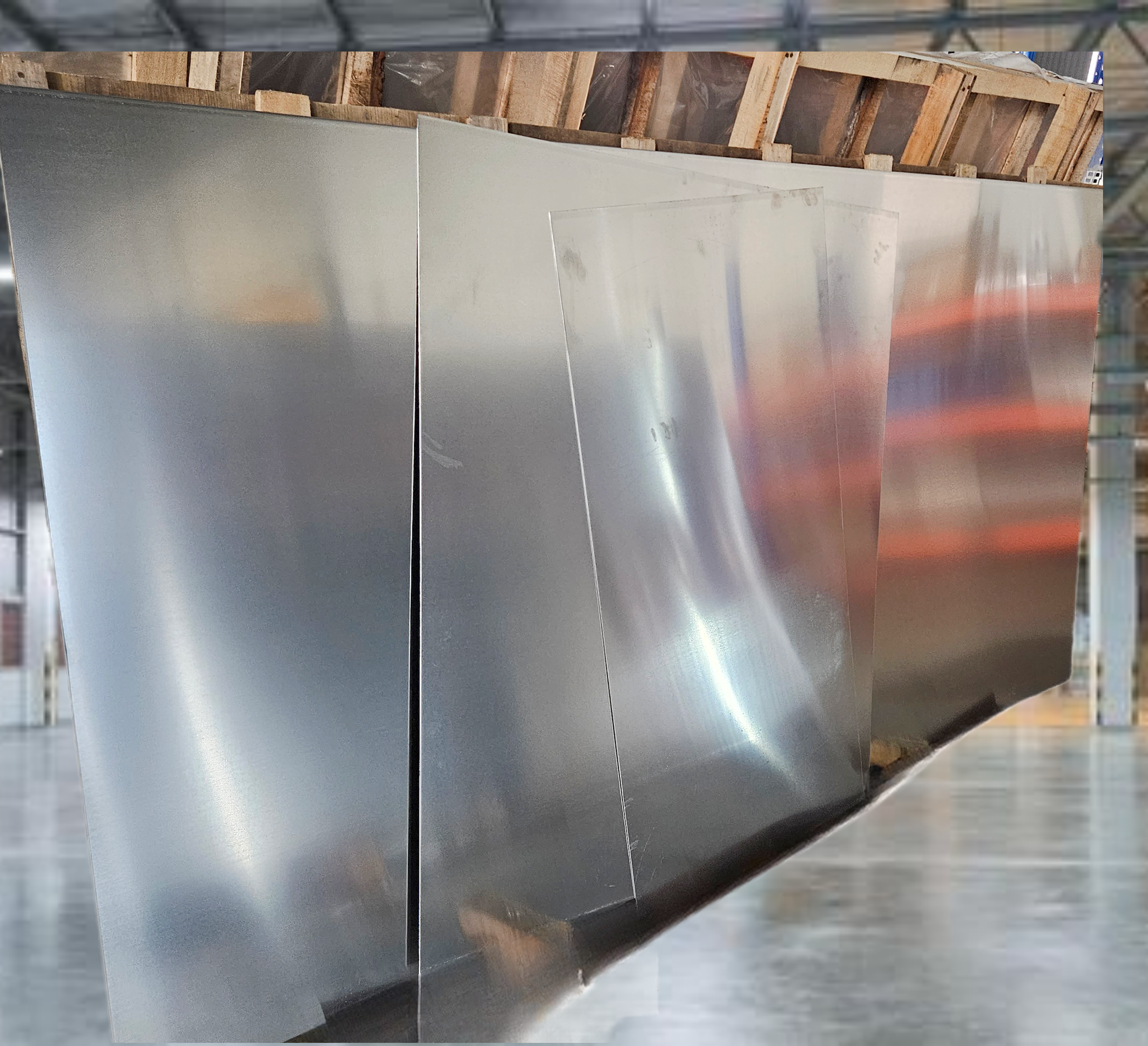

Pictures of Sinrui's production workshop

Radiator product packaging and delivery