| Availability: | |

|---|---|

| Quantity: | |

Cummins QSK23-G3

This product is a high-performance radiator engineered specifically for the Cummins QSK23-G3 engine. It is designed to provide reliable thermal management under high-load conditions, ensuring optimal engine performance and longevity. Built with a heavy-duty core (typically aluminum or copper-brass) and robust construction, it delivers efficient heat dissipation for critical applications in power generation, marine, and industrial sectors.

Features

Precision Engineering: Custom-designed to meet the exact cooling capacity, physical dimensions, and performance specifications of the Cummins QSK23-G3 engine.

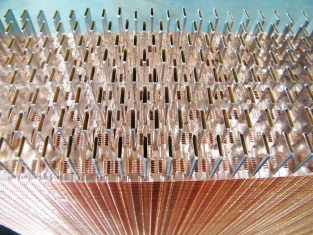

Robust Core Construction: Features a high-efficiency tube-and-fin core, utilizing copper-brass materials for superior thermal conductivity and durability to handle the engine's significant heat output.

Generator Radiator List

| CUMMINS | 4BT, 6BT, 6BTA, NT855, NTA855, KTA19, KTA38, KTA50, QSK23, QSK50, QSK60, QSK78, QSK90, VTA28 |

MTU | 8V1600, 10V1600, 12V2000, 16V2000, 18V2000, 12V4000, 16V4000, 20V4000 |

MITSUBISHI | S6R, S12R, S12H, S16R, S16R2, S12A2 |

PERKINS | 4006, 4006-TAG, 4008-TAG, 4012-46TAG, 4016-61TRG |

CAT | 3512, 3516B, 3508B, C15 |

Maintance and Service

Protective Packaging – Reinforced wooden crates with moisture-proof linings are used for the radiator, preventing copper component corrosion and structural damage during transit.

Precision Pressure Testing – Every radiator is rigorously pressure-tested to ensure it holds perfect pressure, preventing future failures and protecting your engine.

Warranty Coverage – We back our radiator services with a robust 2-year warranty—this commitment far outperforms the industry's typical short-term guarantees (often 6–12 months). It stands as our strong promise to product durability, giving you long-term peace of mind for your investment.

How We Produce

At SINRUI, we ensure every radiator delivers both resilience and efficiency—all thanks to our end-to-end, strict oversight throughout production. From selecting raw materials to completing final welding, each unit is crafted in our advanced workshop, with no detail overlooked in the manufacturing process.

This dedication to quality is reinforced by our ISO 9001 certification—a standard that mandates every radiator pass a series of rigorous tests: leak detection, pressure validation, and thermal performance checks.

Pictures of Sinrui's production workshop, raw materials

Radiator product packaging and delivery