| Availability: | |

|---|---|

| Quantity: | |

MTU 12V4000G21R

A high-performance cooling radiator exclusively engineered for MTU 12V4000G21R high-power diesel engines, it delivers consistent and reliable heat dissipation to support the engine's 2500-3200kW output. Designed to withstand the harsh operating conditions of heavy-duty scenarios, it ensures stable thermal management for prolonged engine operation, making it a critical component for industrial equipment, mining machinery, and large-scale power generation systems.

Features

Engine-Specific Engineering: Precisely matched to MTU 12V4000G21R's cooling system interfaces and thermal load requirements, ensuring seamless installation without modification.

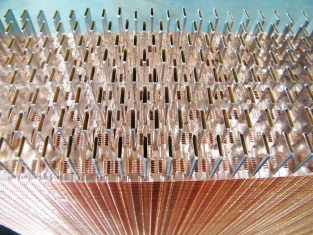

High-Power Heat Dissipation: Optimized core design (with enhanced heat transfer surface area) to efficiently handle the engine's high heat output, preventing overheating during peak load operation.

Harsh Environment Durability: Built with robust materials and reinforced structures to resist vibration, temperature fluctuations (-30°C to 130°C), and dust/debris—common in industrial and mining settings.

Generator Radiator List

| CUMMINS | 4BT, 6BT, 6BTA, NT855, NTA855, KTA19, KTA38, KTA50, QSK23, QSK50, QSK60, QSK78, QSK90, VTA28 |

MTU | 8V1600, 10V1600, 12V2000, 16V2000, 18V2000, 12V4000, 16V4000, 20V4000 |

MITSUBISHI | S6R, S12R, S12H, S16R, S16R2, S12A2 |

PERKINS | 4006, 4006-TAG, 4008-TAG, 4012-46TAG, 4016-61TRG |

CAT | 3512, 3516B, 3508B, C15 |

Maintance and Service

Custom Cooling Solutions – We engineer radiators precisely aligned with your unique engine requirements and operational environmental conditions.

Protective Packaging – Reinforced wooden crates with moisture-proof linings are used for the radiator, preventing copper component corrosion and structural damage during transit.

How We Produce

Each generator radiator undergoes specialized CAD thermal flow simulation and structural stress analysis—tailored to the high thermal conductivity of copper tubes—to optimize heat dissipation efficiency under continuous generator operation.

Fin-tube assemblies use high-precision mechanical tube expansion to join louvered copper fins with seamless copper tubes—ensuring 100% contact (minimizing thermal resistance) and 40% more heat transfer area vs. standard versions.

Vacuum brazing (with copper-phosphorus filler) makes airtight copper joints (resisting thermal cycles); critical header-to-tube connections get extra argon arc welding to prevent vibration leakage.

Pictures of Sinrui's production workshop, raw materials

Radiator product packaging and delivery