| Availability: | |

|---|---|

| Quantity: | |

Perkins 4006-23TAG3A

A purpose-built cooling component engineered exclusively for Perkins 4006-23TAG3A diesel engines, this radiator delivers consistent heat dissipation to support the engine's 1000-1500kW output in industrial power generation, heavy construction, and mining applications.

Features

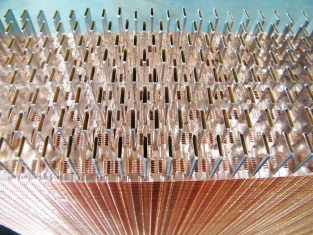

Tailored Core Design: Seamless TP2 deoxidized copper tubes paired with louvered copper fins (integrated via precision mechanical tube expansion) for 100% fin-tube contact—minimizing thermal resistance and optimizing cooling for the engine's steady-load operation.

Durability for Harsh Conditions: Vacuum-brazed joints (copper-phosphorus filler) resist thermal cycles (-30°C to 120°C), while critical header-to-tube connections are reinforced with argon arc welding to prevent vibration-induced leakage.

Rigorous Quality Validation: Each unit undergoes 2.0MPa hydrostatic testing and helium leak detection to ensure reliability, aligning with Perkins' industrial equipment standards.

Generator Radiator List

| CUMMINS | 4BT, 6BT, 6BTA, NT855, NTA855, KTA19, KTA38, KTA50, QSK23, QSK50, QSK60, QSK78, QSK90, VTA28 |

MTU | 8V1600, 10V1600, 12V2000, 16V2000, 18V2000, 12V4000, 16V4000, 20V4000 |

MITSUBISHI | S6R, S12R, S12H, S16R, S16R2, S12A2 |

PERKINS | 4006, 4006-TAG, 4008-TAG, 4012-46TAG, 4016-61TRG |

CAT | 3512, 3516B, 3508B, C15 |

Maintance and Service

Quality Components – For industrial radiators, every part undergoes multi-step rigorous inspection—from raw material screening to finished product validation—to guarantee uninterrupted operation of your engine-equipped equipment.

Custom Cooling Solutions – We engineer radiators tailored to your engine's unique thermal needs and specific operating scenarios ensuring precise alignment with the engine's requirements.

Protective Packaging – Industrial radiators are packed in reinforced wooden crates with moisture-proof linings, effectively preventing corrosion of copper components and structural damage during transit.

How We Produce

Generator radiator manufacturing follows a strict workflow: first, specialized CAD modeling and thermal simulation (tailored to the generator's heat needs) to optimize cooling design; next, high-quality materials (e.g., copper tubes, fins) are sourced and inspected; then, precision tube expansion joins fins and tubes, with vacuum brazing for tight, heat-resistant joints—critical connections get argon arc welding for vibration resistance; each unit undergoes testing (e.g., pressure checks, leak detection) before final assembly and packaging in reinforced, moisture-proof crates, with full quality tracing to meet generator requirements.

Pictures of Sinrui's production workshop, raw materials

Radiator product packaging and delivery