| Availability: | |

|---|---|

| Quantity: | |

Cummins KTA38-G5 Engine

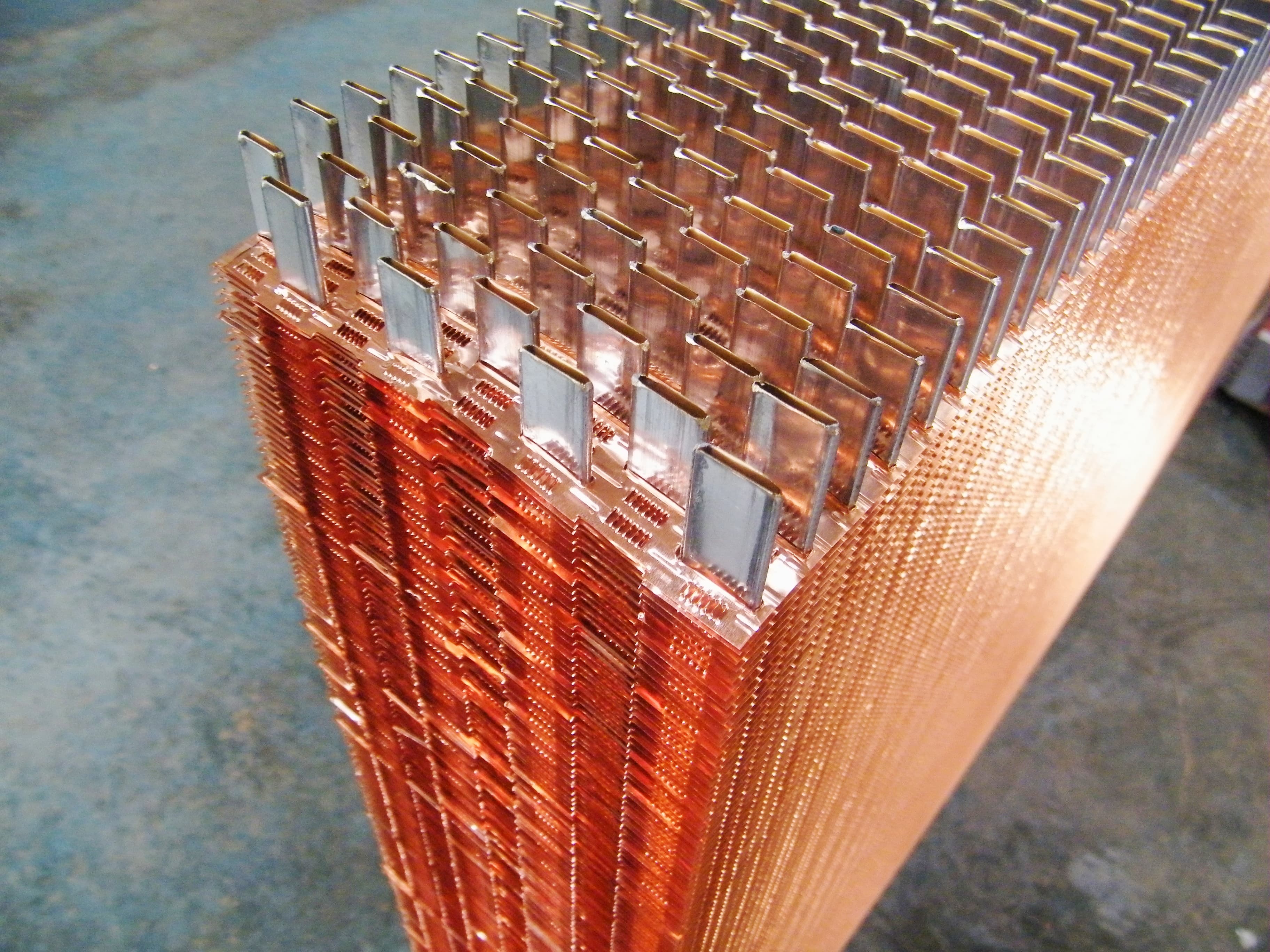

The Cummins KTA38-G5 engine often operates under continuous high load in harsh environments like mining and heavy machinery. To address this, we have comprehensively reinforced this dedicated radiator. The core features thickened tubes with high-flow, low-flow-resistance design to handle challenging water conditions and minimize clogging risks. The cooling fins are specially designed to resist dust clogging, and the vulnerable outer surfaces are protected by a robust guard mesh. These enhancements significantly boost the radiator's adaptability and reliability in dusty, high-impact environments, ensuring stable cooling performance for the engine under the most demanding conditions.

Features

Equipped with efficient pressure relief and air vent valves to ensure safe and stable system operation, preventing airlocks and over-pressurization.

Utilizes low-power consumption, high-speed fans and motors that deliver required cooling performance while minimizing parasitic power draw.

Generator Radiator List

CUMMINS | 4BT,6BT,6BTA,NT855,NTA855,KTA19,KTA38,KTA50,QSK23,QSK50,QSK60,QSK78,QSK90,VTA28 |

MTU | 12V2000,16V2000,18V2000,12V4000,16V4000,20V4000 |

MITSUBISHI | S6R,S12R,S12H,S16R,S16R2,S12A2 |

PERKINS | 4006,4006-TAG,4008-TAG,4012-46TAG,4016-61TRG |

CAT | 3512,3516B,3508B,C15 |

Maintance and Service

Rapid Shipping – Standard models are available for dispatch within 24 hours to minimize equipment downtime.

Custom Cooling Solutions – We design radiators tailored to your specific engine needs and environmental conditions.

How We Produce

Our manufacturing workshop is equipped with industry-leading automated production lines. From core vacuum brazing furnaces to high-speed precision fin presses, every piece of equipment serves to ensure superior radiator quality. Vacuum brazing technology allows the core to be formed in an oxide-free environment, creating uniform and high-strength joints that fundamentally eliminate leakage risks. Combined with the application of robotic welding arms, we achieve high consistency and precision in welding key structural components, guaranteeing intrinsic product quality and long-term durability.

Pictures of Sinrui's production workshop