| Availability: | |

|---|---|

| Quantity: | |

323-1741

The CAT 323-1741 radiator is more than an isolated component; it is an integral part of the precision engineering of the CAT 795F's powertrain. Its exact OEM specifications ensure perfect thermal management synergy with critical assemblies like the engine and hydraulic system, allowing the truck's full performance potential to be realized. This system-level compatibility prevents power derating or efficiency loss due to inadequate cooling, guaranteeing that the machine maintains its designed performance even under peak loads. It is fundamental to achieving maximum production output and fulfilling the equipment's intended design purpose.

Features

The high-density fin design maximizes heat dissipation within a limited space, delivering exceptional heat dissipation efficiency.

Aluminum Radiator List

CAT | 464-9054,464-9055,243-5063 ,251-6149,464-9056,464-9046,370-9331,331-5138,464-9049,370-9333,533-8330,534-7440,535-4527,260-0354,119-4774,528-0686,219-1073,612-432,231-8103,204-7184,163-4058,163-4064,188-7475 |

KOMATSU | 56E-07-21133,561-03-81280,561-03-81632,561-03-81652,561-03-81642,21N-03-37412,21N-03-43510 ,21T-03-31711,95809040,95019940, 427-03-22820,569-03-89191,6212-62-4100,195-03-63114,195-03-65181,423-03-32211,426-03-37571 |

HITACHI | 1386-621-100,1381-639-801,1381-639-8020,1381-639-8030,4682425, 4682426,4444691, 4658096,4427952,4729782,4421620,335611,4439687,YA00008446 |

LIEBHERR | 10000392,5617986,5617987,5611936,10333648,10333649,11823532,11821219,11821218,5611937 |

Maintance and Service

Easy-Replacement Parts – Interchangeable components simplify maintenance and reduce service costs.

On-Site Service Options – Professional installation and maintenance support can be provided at your facility.

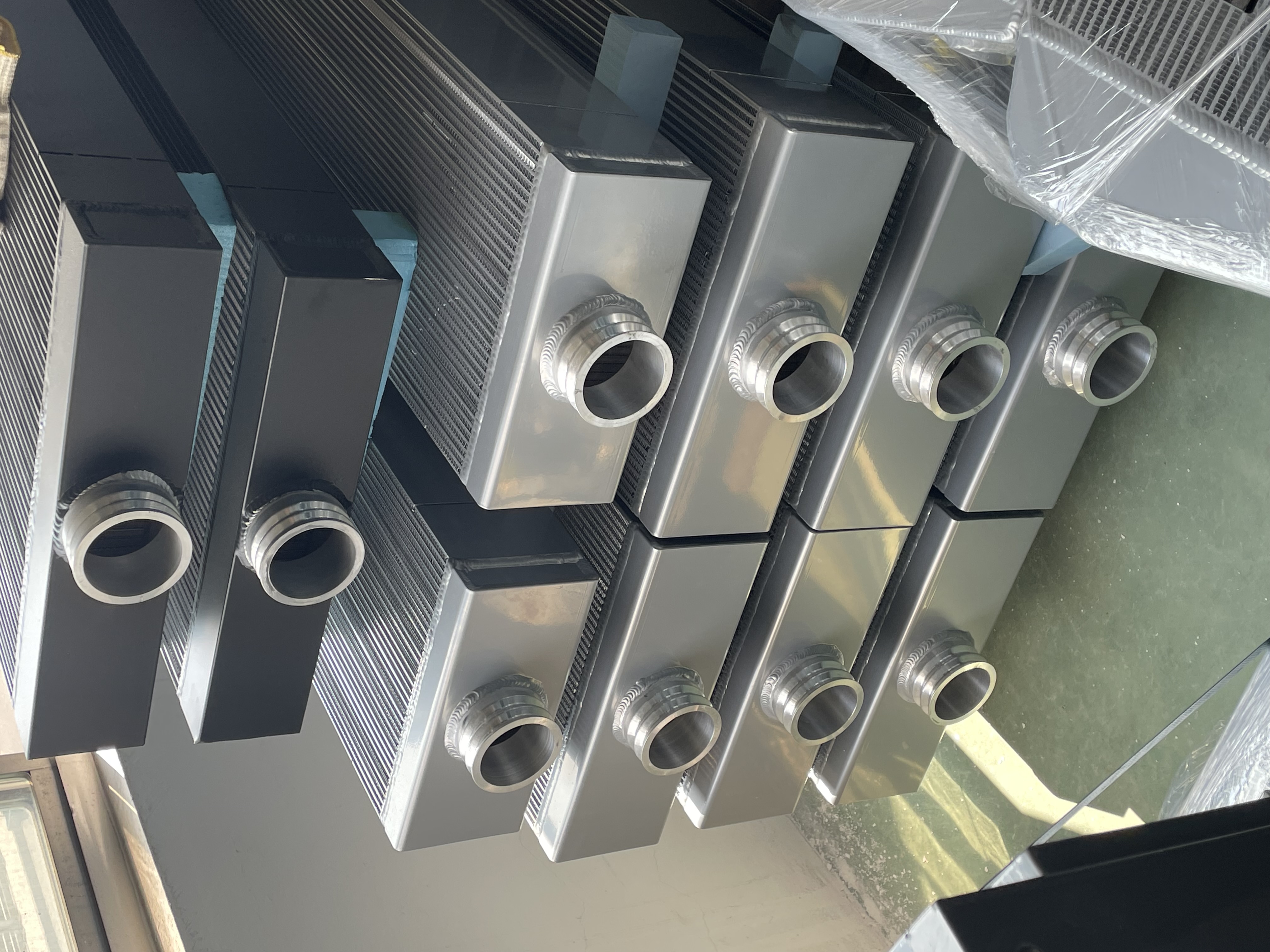

How We Produce

At the core of our production lies the deep integration of advanced manufacturing processes with full-process quality control. Every SINRUI radiator, from the receipt of high-purity aluminum materials to final dispatch, must pass a multi-node validation system that includes material inspection, vacuum brazing process control, pressure and leak testing, and final performance verification. Within the ISO 9001 certified quality management framework, we conduct rigorous leak, pressure cycle, and thermal cycle tests. This ensures that each product not only performs exceptionally upon shipment but also delivers lasting cooling reliability under harsh operating conditions. This end-to-end control guarantees consistent outstanding durability and stable performance batch after batch.

Pictures of Sinrui's production workshop