| Availability: | |

|---|---|

| Quantity: | |

364-6099

Radiator Model 364-6099 is specifically designed for the CAT 773E Off-highway Truck. Its structure features a network of tubes and fins, specifically designed to maximize surface area for effective heat transfer. When hot compressed air flows through the core, this design works to draw heat away from the air and transfer it to the tube walls—ensuring the air cools down as intended.

Features

Prevents leakage even in high-pressure operating conditions.

Higher oxygen concentration boosts combustion efficiency and improves engine performance.

Aluminum Radiator List

CAT | 298-1226, 230-2966, 113-9539, 7C-1420, 220-0538, 213-8188, 185-7980, 243-5063, 320-0214, 186-0117, 230-5006, 281-3514, 359-9393, 245-9334, 236-8741, 245-4622, 250-4453, 3N-4363, 3N-4364, 230-2966, 186-9526, 272-5592, 2W-0181, 210-8030, 395-3755, 443-2101 |

KOMATSU | 56E-07-21133, 561-03-81280, 561-03-81632, 561-03-81652, 561-03-81642, 21N-03-37412, 21N-03-41110, 21N-03-43510, 21T-03-31160, 21T-03-31711, 95019940, 95809040 |

HITACHI | 4682425, 4682426, 4444691, 4658096, 4427952, 4729782, 4421620, 335611, 4439687, YA00008446, 1386-621-100, 1381-639-801, 1381-639-8020, 1381-639-8030 |

LIEBHERR | 10000392, 5617986, 5617987, 11823532, 11821219, 11821218, 5611936, 5611937, 10333648, 10333649 |

Maintance and Service

Quality Components: Every part goes through rigorous inspection—all to guarantee your equipment runs without interruption, keeping your operations on track.

Fast Delivery: We ship in-stock standard parts within 24 hours, so you get quick order fulfillment and shorter wait times, reducing delays to your work.

How We Produce

Our aftercoolers go through advanced CAD modeling and thermal simulation to optimize airflow and cooling efficiency. We use top-tier aluminum alloy, which offers excellent thermal conductivity and corrosion resistance—key for durability. Our fin-and-tube assemblies are precision-made to maximize heat transfer surface area, while vacuum brazing ensures leak-free, strong bonding between components. Critical joints are also reinforced with TIG or MIG welding for extra reliability.

Every unit undergoes high-pressure testing and airtightness checks to ensure zero leakage. Before packaging, all components are assembled, inspected, and tested according to strict quality standards, so you can trust the final product’s performance.

Pictures of Sinrui's production workshop, raw materials

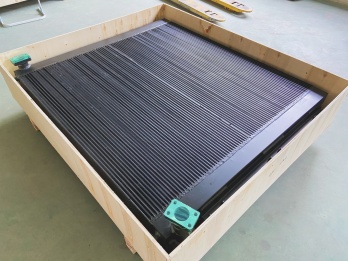

Radiator product packaging and delivery