| Availability: | |

|---|---|

| Quantity: | |

387-4367

Radiator Model 387-4367 is specifically designed for the CAT 844K Wheel Dozer. As part of the engine's cooling system, the radiator core works to dissipate heat from the coolant. It consists of rows of cooling tubes that connect to the engine block and enable the flow of hot coolant through the block. Around the core, there are also fins; these fins expand the core's surface area, which in turn improves heat transfer.

Features

The air fin type of the radiator core is square wave.

The internal volume of the radiator core is 3.51 liters.

The electrophoretic coating and UV protective coating prevent the cooler core from wear, thus enhancing its durability.

Aluminum Radiator List

CAT | 298-1226, 230-2966, 113-9539, 7C-1420, 220-0538, 213-8188, 185-7980, 243-5063, 320-0214, 186-0117, 230-5006, 281-3514, 359-9393, 245-9334, 236-8741, 245-4622, 250-4453, 3N-4363, 3N-4364, 230-2966, 186-9526, 272-5592, 2W-0181, 210-8030, 395-3755, 443-2101 |

KOMATSU | 56E-07-21133, 561-03-81280, 561-03-81632, 561-03-81652, 561-03-81642, 21N-03-37412, 21N-03-41110, 21N-03-43510, 21T-03-31160, 21T-03-31711, 95019940, 95809040 |

HITACHI | 4682425, 4682426, 4444691, 4658096, 4427952, 4729782, 4421620, 335611, 4439687, YA00008446, 1386-621-100, 1381-639-801, 1381-639-8020, 1381-639-8030 |

LIEBHERR | 10000392, 5617986, 5617987, 11823532, 11821219, 11821218, 5611936, 5611937, 10333648, 10333649 |

Maintance and Service

Customized Solutions – We provide tailor-made cooling systems to meet the exact requirements of your engines and working environments.

How We Produce

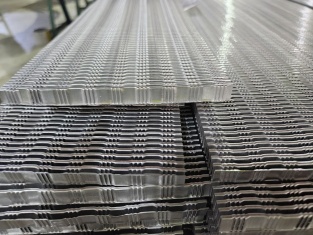

Every aftercooler is subjected to advanced CAD modeling and thermal simulation, specifically to optimize airflow and cooling efficiency. We utilize high-quality aluminum alloy—this material boasts exceptional thermal conductivity and corrosion resistance, ensuring reliable long-term performance. Fin-and-tube assemblies are manufactured with high precision, engineered to maximize the surface area available for heat transfer. For component bonding, vacuum brazing is employed to achieve leak-free, robust connections; additionally, critical joints are further reinforced using TIG or MIG welding for enhanced structural stability.

Each unit is put through rigorous high-pressure testing and airtightness inspection to guarantee zero leakage. Prior to packaging, all components undergo assembly, inspection, and testing in line with stringent quality standards—leaving no room for deviations that could affect performance.

Pictures of Sinrui's production workshop, raw materials

Radiator product packaging and delivery