| Availability: | |

|---|---|

| Quantity: | |

The 534-3807 oil cooler is a high-performance hydraulic system cooling device designed specifically for industrial applications. It effectively reduces hydraulic oil temperature, ensuring stable operation and long equipment life. Utilizing advanced cooling technology, this oil cooler is suitable for a variety of mechanical equipment requiring temperature control, hydraulic systems, engines, and other industrial applications with high heat loads.

Features

Efficient Cooling Performance – The 534-3807 oil cooler utilizes highly efficient heat exchange technology to rapidly reduce oil temperature in hydraulic systems, ensuring optimal operating temperatures. It boasts a cooling capacity of up to 30kW and can handle hydraulic oil flows of up to 150L/min.

High-Quality Materials – This oil cooler utilizes corrosion-resistant materials (such as an aluminum alloy housing and copper tubing) to withstand high temperatures and high pressures, ensuring long-term, stable operation in harsh environments. The housing also features a surface anti-corrosion treatment to prevent corrosion from prolonged contact with liquids.

Aluminum Radiator List-

| CAT | 2W0181, 2W5539, 2W5540, 2W6632, 7W2173, 9Y3318, 7C3385, 2W6587, 2W6593, 7W5455, 360-9273, 312-8338, 326-3870, 312-8339, 204-0884, 443-2101, 375-5673, 230-2917, 281-3516,111-5059 |

| Komatsu | 56E-07-21133, 561-03-81280, 561-03-81632, 561-03-81652, 561-03-81642, 21N-03-37412, 21N-03-41110, 21N-03-43510, 21T-03-31160, 21T-03-31711 |

| Liebherr | 10000392, 5617986, 5617987, 11823532, 11821219, 11821218, 5611936, 5611937, 10333648, 10333649, |

| Hitachi | 1386-621-100, 1381-639-801, 1381-639-8020, 1381-639-8030, 4682425, 4682426, 4444691, 4658096, 4427925, 4729782, 4421620, 335611, 4439687, YA00008446 |

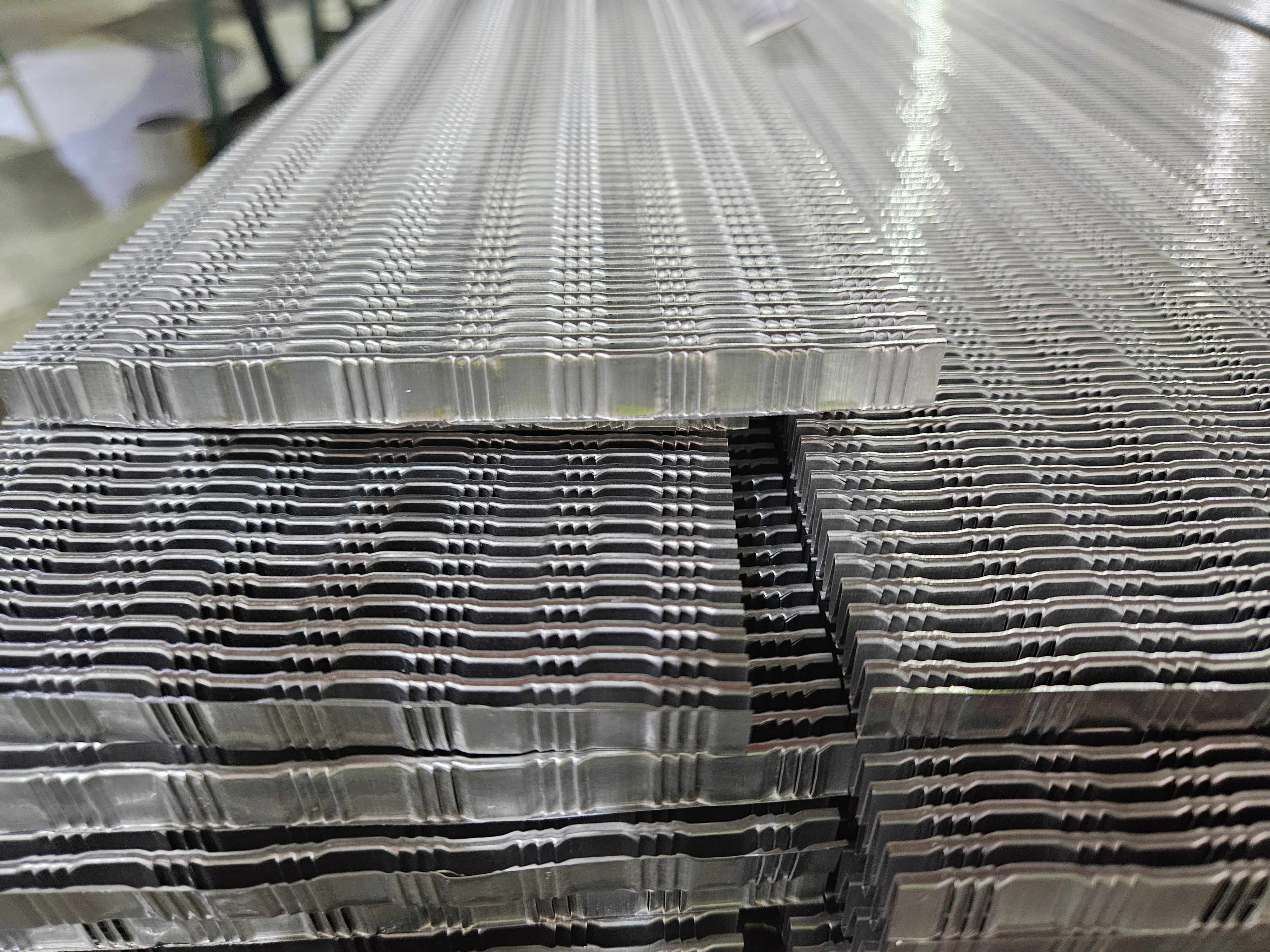

How We Produce

All materials are rigorously screened to ensure compliance with international standards. The use of copper tubing and aluminum alloy ensures cooling efficiency and durability. Advanced heat exchange technology improves heat exchange efficiency, reduces temperature control errors, and ensures that the oil temperature remains within the set range. Every component of the oil cooler is precision-machined using CNC machine tools to ensure precise dimensions for optimal heat dissipation and device stability. Each oil cooler undergoes rigorous pre-shipment testing, including high-pressure leak detection, heat exchange efficiency testing, and visual inspection, to ensure it meets factory standards.

Pictures of Sinrui's production workshop

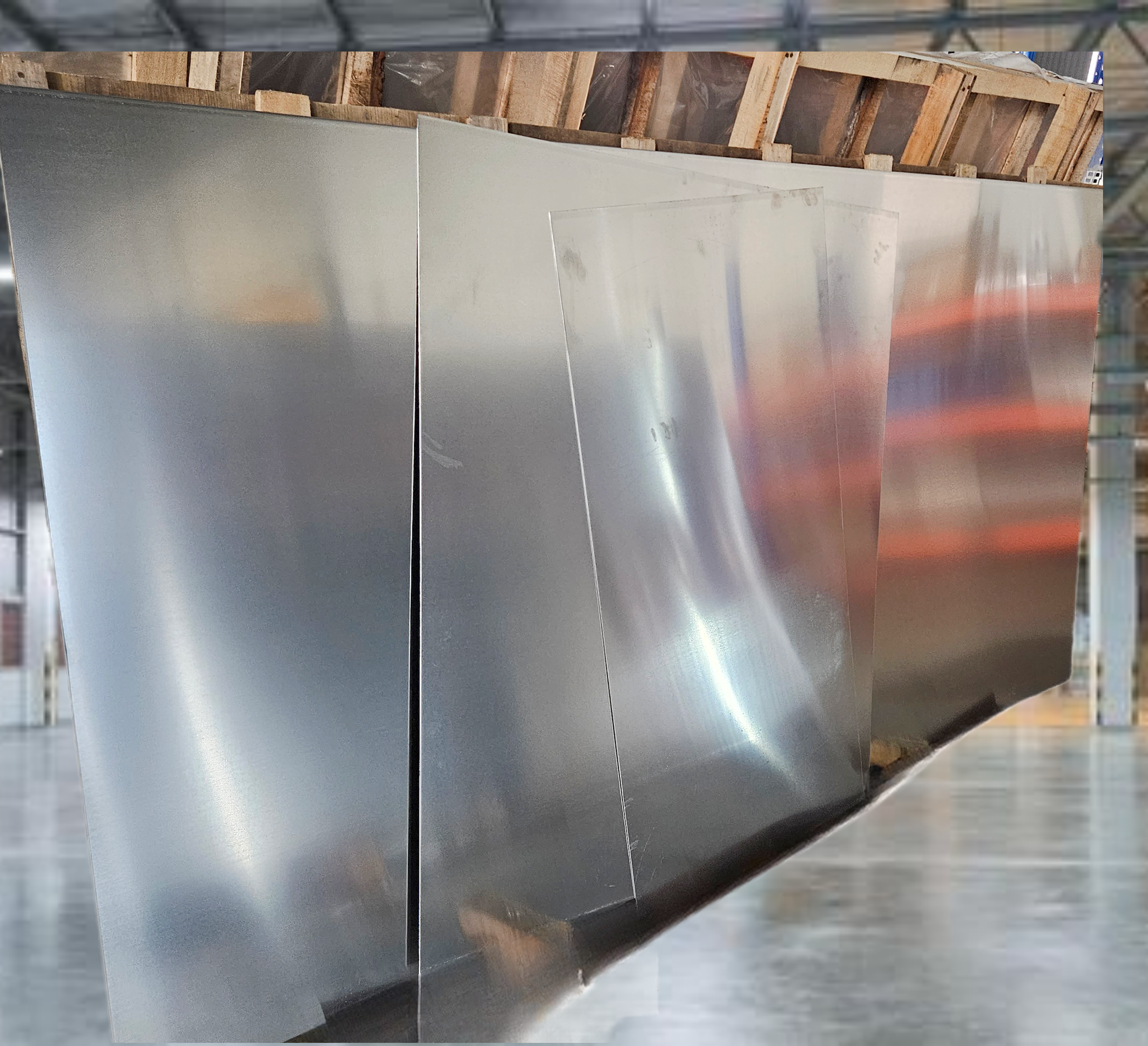

Radiator product packaging and delivery