| Availability: | |

|---|---|

| Quantity: | |

MTU 16V2000

The MTU 16V2000 Radiator is a large cooling component designed for MTU's 16V2000 series engines, often used in generator sets. These radiators are specialized, with some models featuring a "unit mounted" design and specific coolant flow rates and heat rejection capacities, depending on the engine model and application (e.g., standby vs. prime power).

Features

Radiators are specifically engineered for different versions of the 16V2000 engine (e.g., G25, G65, DS1000), with variations in core size, coolant capacity, and heat rejection.

Many come as a "unit mounted" system, meaning the radiator is integrated directly with the generator set.

They are used in various settings, such as industrial, commercial, and backup power systems, with ratings that can support continuous or standby operation.

Generator Radiator List

| CUMMINS | 4BT, 6BT, 6BTA, NT855, NTA855, KTA19, KTA38, KTA50, QSK23, QSK50, QSK60, QSK78, QSK90, VTA28 |

MTU | 8V1600, 10V1600, 12V2000, 16V2000, 18V2000, 12V4000, 16V4000, 20V4000 |

MITSUBISHI | S6R, S12R, S12H, S16R, S16R2, S12A2 |

PERKINS | 4006, 4006-TAG, 4008-TAG, 4012-46TAG, 4016-61TRG |

CAT | 3512, 3516B, 3508B, C15 |

Maintance and Service

2-Year Warranty – Every radiator is backed by a 2-year warranty, ensuring long-term reliability and peace of mind.

Customized Solutions – We provide tailor-made cooling systems to meet the exact requirements of your engines and working environments.

How We Produce

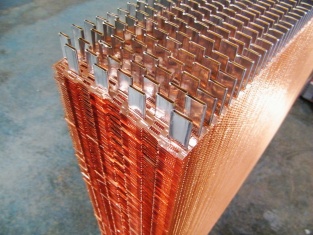

Every SINRUI radiator features full-lifecycle tech-driven quality control, spanning from ISO-9001 foundry production to core completion: raw materials are precision-stamped via CNC systems, joined by robotic welding with real-time parameter monitoring, then subjected to rigorous leak tightness, pressure endurance, and thermal efficiency testing—delivering out-of-the-box reliability for long, fault-free service.

Pictures of Sinrui's production workshop, raw materials

Radiator product packaging and delivery